Chain-On-Edge (COE) conveyors are one of the most practical and underappreciated tools in the finishing world.

Jeff SmekerCommonly used in powder and liquid coating applications, they’re especially suited for handling small-to-medium parts that require controlled rotation during processing. Yet despite their wide use, COE systems often go unnoticed in broader industry discussions.

Jeff SmekerCommonly used in powder and liquid coating applications, they’re especially suited for handling small-to-medium parts that require controlled rotation during processing. Yet despite their wide use, COE systems often go unnoticed in broader industry discussions.

This article takes a closer look at how they work, where they shine, and what design considerations matter when you’re specifying one.

What Is a Chain-On-Edge Conveyor?

A Chain-On-Edge conveyor is a continuously driven chain with upright spindles mounted at regular intervals. These spindles hold parts and can rotate freely, either mechanically or via servo control, as they travel through the process. This allows for even coating, efficient material transfer, and repeatable orientation throughout the system.

Typical applications include spray coating, curing, washing, inspection, and robotic handling. COE systems are particularly useful when parts need to spin under a spray gun or robot to ensure 360° coverage.

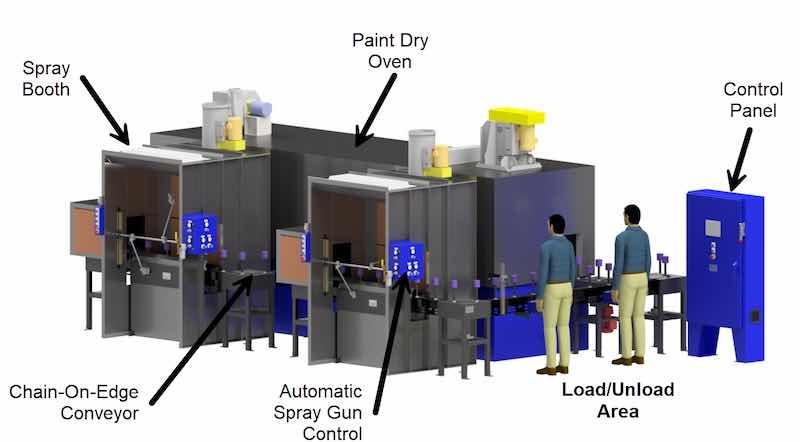

An example of a Chain-On-Edge conveyor system.

An example of a Chain-On-Edge conveyor system.

Why Use a COE System?

COE conveyors offer several advantages:

- Part Rotation: Controlled or passive rotation makes them ideal for cylindrical or round parts needing full-surface coverage.

- Space Efficiency: COE lines can be configured in compact loops, minimizing the need for floor space.

- Consistent Orientation: Precision spindle alignment provides reliable part positioning for downstream operations.

- Process Flexibility: COE conveyors support multiple stages—pre-treatment, spray, cure—in one continuous path.

You’ll find them in industries ranging from automotive to aerospace, electronics to defense.

Design Considerations That Matter

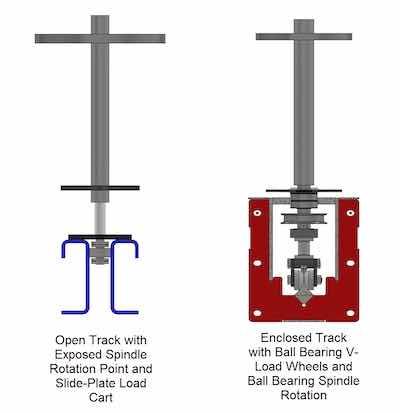

Not all COE conveyor systems are built the same, and that matters. Some are engineered with tight tolerances, long-life spindle assemblies, robust chain designs, and stable fixturing. Others may cut corners with loose components, minimal bearing support, poor rotational control, or inadequate part stability. These differences can dramatically affect coating quality, maintenance requirements, and long-term reliability.

Not all COE conveyor systems are built the same, and that matters. Some are engineered with tight tolerances, long-life spindle assemblies, robust chain designs, and stable fixturing. Others may cut corners with loose components, minimal bearing support, poor rotational control, or inadequate part stability. These differences can dramatically affect coating quality, maintenance requirements, and long-term reliability.

The top design consideration in any COE system is straightforward: how can the part be securely held on the spindle?

Everything starts there. If the part can’t be fixtured properly—with adequate stability, repeatable positioning, and allowance for coating access—then the rest of the system is compromised from the start.

Other important factors to evaluate include:

- Spindle and Rotation Requirements: Will the part need to spin freely, index to specific angles, or stay locked in place?

- Load Requirements: Part weight and height drive the choice of spindle diameter and structural support.

- Environmental Demands: Will the system be exposed to wash stages, ovens, or hazardous locations? Materials and design must be process-appropriate.

Ultimately, a COE system’s long-term performance depends on getting the mechanical fundamentals right—from part fixturing to spindle control to structural durability. Overlook those, and you’re designing for failure from day one.

When COE Isn’t the Right Fit

While versatile, COE isn’t ideal in every application. Consider alternatives when:

- Parts are very large and/or irregularly shaped, making stable spindle fixturing impractical.

- Production requirements are too low to justify the cost and complexity of an automated COE system.

- Elevation changes are required in the layout, as COE systems typically operate in a single horizontal plane.

Summary

Robotic unloading of wheels on a powder coating system.COE conveyors provide precise part handling, rotational control, and efficient process flow in finishing systems. But like any technology, execution is everything. A well-engineered COE system can run reliably for decades with minimal maintenance. A poorly designed one? Not so much.

Robotic unloading of wheels on a powder coating system.COE conveyors provide precise part handling, rotational control, and efficient process flow in finishing systems. But like any technology, execution is everything. A well-engineered COE system can run reliably for decades with minimal maintenance. A poorly designed one? Not so much.

Whether you’re planning a new line or upgrading an existing system, pay close attention to how the COE conveyor is designed, not just what it’s supposed to do.

Jeff Smeker is Vice President of Engineering at Precision Conveyor Technologies, where he has spent almost 30 years designing turnkey automated finishing systems. He specializes in Chain-On-Edge conveyor systems for liquid, powder, and adhesive coating applications. Visit www.precisionconveyor.com.