In his book “The Seven Habits of Highly Effective People,” Stephen R. Covey writes: “Begin with the end in mind.”

To begin with the end in mind means to start with a clear understanding of your direction and final goal. In the finishing industry, the goal is to provide a finish that meets and, when possible, exceeds the criteria given by the customer. The single most important step one can take to achieve this goal is to give careful thought and consideration to the cleaning process prior to the final finishing operation.

The level of contamination and the cleanliness requirements will vary, depending on the finish. Once the required cleanliness level has been determined, the next step is to identify the characteristics and process parameters required to achieve it reliably. This article identifies a number of key factors that contribute to the effectiveness and final success of the cleaning process utilizing aqueous cleaning technology. Aqueous cleaning lines have been proven successful in a number of applications, including electroplating, powder coating, and vacuum coating. Each line is specifically designed for that application—taking into consideration the substrate material, production throughput, part configuration, and type of contaminants.

Editor’s Note: This article was initially written in 1999.

Effects of Cleaning On Coating Performance

Depending on the finish being applied, improper cleaning may result in total failure (poor adhesion); surface irregularities, including roughness, pits, voids, or porosity; and/or localized adhesion problems in difficult-to-reach areas (such as countersinks or holes).

Additional coating failures can occur during corrosion testing, resulting in complete or partial failure of the batch. Other performance characteristics may include hardness, wear resistance, and color uniformity. However, these factors tend to involve problems within the post-coating or plating process rather than the cleaning process.

Types of Contaminants

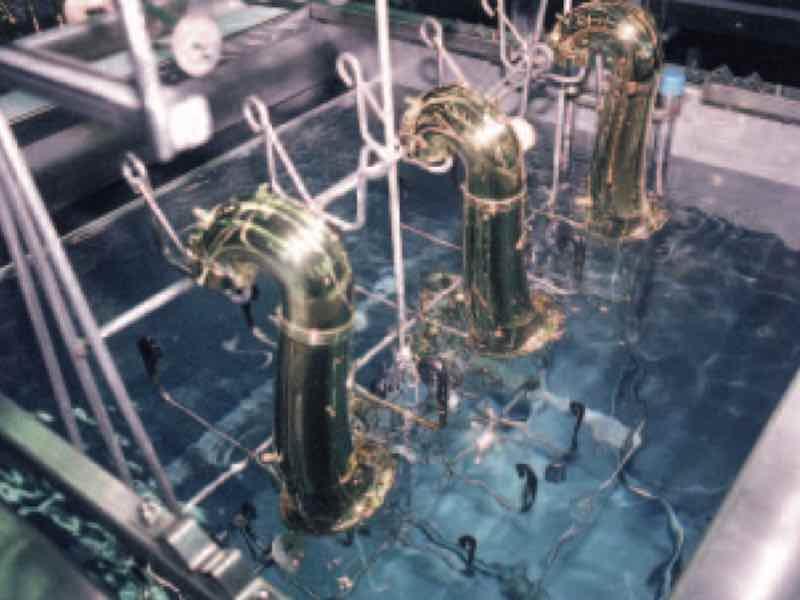

An ultrasonic cleaning system removes polishing compounds from these brass musical instrument components prior to lacquer coating. (Photo courtesy of CAE Blackstone.)The type of contamination will vary depending on the application, substrate material, and manufacturing processes carried out prior to finishing. Contaminants may include machining lubricants, dyes, oil, grease, waxes, buffing compounds, metallic particles, and fingerprints. Polishing and buffing compounds are, perhaps, the most difficult contaminants to remove. Their removal becomes even more difficult if they are baked on or if they are allowed to dry out prior to cleaning.

An ultrasonic cleaning system removes polishing compounds from these brass musical instrument components prior to lacquer coating. (Photo courtesy of CAE Blackstone.)The type of contamination will vary depending on the application, substrate material, and manufacturing processes carried out prior to finishing. Contaminants may include machining lubricants, dyes, oil, grease, waxes, buffing compounds, metallic particles, and fingerprints. Polishing and buffing compounds are, perhaps, the most difficult contaminants to remove. Their removal becomes even more difficult if they are baked on or if they are allowed to dry out prior to cleaning.

The binders or waxes found in buffing and polishing compounds, if not thoroughly removed, will cause defects and eventually contaminate the entire finishing process.

Other types of contaminants include plating salts, chemical residue, or films left on the substrate prior to coating. This can be a result of poor rinsing or incompatibility of chemistries in the line. Inadequate rinsing, filtration, or poor-quality rinse water will result in surface contamination, water spots, and subsequent difficulties in the finishing process.

Substrate Material

The composition or chemistry of the base metal is one of the most important factors when choosing a cleaning process. The cleaning chemistry must be compatible with the substrate material or base metal. In addition to the potential for etching or pitting of the base metal by the process chemistry, there is the possibility of erosion caused by improper selection of ultrasonic equipment. In this situation, excessive ultrasonic power or incorrect ultrasonic frequency may cause surface erosion. In many cases, however, pitting or craters visible after finishing are a result of poor electroplating techniques or preexisting defects in the base material (zinc diecasts).

The alkalinity or pH level is an important factor when working with aluminum, zinc, or copper alloys.

Variations within the alloys (differing percentages of lead or zinc in copper alloys, for example) will produce different results when evaluating the base metal’s ability to withstand attack from alkaline or acidic cleaners. Ferrous materials can flash-rust between cleaning process steps. The process flow, which includes the number of process baths, rinses, and dwell time between baths, can be adjusted to minimize this problem, along with the timely addition of rust inhibitors prior to drying.

Choice of Chemistry

This 900-gallon ultrasonic cleaning tank is an integral part of a high-throughput plating line.The correct choice of pre-treatment chemistry is the single most important step in ensuring consistent finish quality and performance. The addition of ultrasonic technology, mechanical agitation, and correct filtration goes a long way in improving the performance of the chemistry and extending the life of the bath. No equipment enhancement can make the chemistry work, however, if it has not been chosen correctly or is being operated outside the manufacturer’s recommendations.

This 900-gallon ultrasonic cleaning tank is an integral part of a high-throughput plating line.The correct choice of pre-treatment chemistry is the single most important step in ensuring consistent finish quality and performance. The addition of ultrasonic technology, mechanical agitation, and correct filtration goes a long way in improving the performance of the chemistry and extending the life of the bath. No equipment enhancement can make the chemistry work, however, if it has not been chosen correctly or is being operated outside the manufacturer’s recommendations.

In many instances, problems arise when new equipment is installed without prior process evaluation or when the chemistry that was used for evaluation is changed after installation. The marriage between chemistry and equipment is critical. To minimize risks and shorten the learning curve, one should choose an equipment manufacturer that works closely with chemical suppliers.

Alkaline chemistries are most commonly used to remove oils, grease, waxes, and polishing compounds. Applied by immersion or spray, the alkaline bath is usually followed by a series of rinses. The main processes responsible for the removal of surface contaminants are saponification, mechanical displacement, emulsification, and dispersion.

The choice of immersion or spray depends on the application. In the case of buffing and polishing compounds, the most efficient and satisfactory method of cleaning is immersion combined with ultrasonics.

The main concern with emulsion-type cleaners is the oil-like residue left on the parts after cleaning. Thorough rinsing and the use of a secondary cleaning with an alkaline detergent will remove this oil-like residue prior to finishing. Ultrasonic technology significantly improves the cleaning efficiency of immersion-type systems. Spray cleaning provides the advantages of power impingement and no re-deposition of contaminants.

Electrolytic alkaline cleaning is often a necessary step between the immersion cleaning and plating process. Similar to the mechanical effects of ultrasonic cleaning, electrolytic cleaning provides a high level of agitation close to the work surface— the result of gas evolution at the surface of the part. This method can be particularly effective at removing polishing compounds, fine inert particles, or abrasives.

Pre-cleaning in the immersion type cleaner, however, is necessary to reduce the level of contamination and increase the life of the electrolytic cleaning solution.

Acid cleaning is the next process used to remove oxide layers and other contaminants. The cleaner is usually a solution of mineral acid, organic acid, or acid salt combined with a wetting agent and detergent. Acid cleaning may not be necessary for painting or powder coating applications. Immersion cleaning is the most common method used for acid cleaning.

Ultrasonic Technology

Today, as a result of advancements in technology, ultrasonic cleaning has matured into a cost-competitive and highly effective technology that is widely used in a number of plating and coating applications.

Ultrasonic energy is now used extensively in critical cleaning applications to both speed up and enhance the cleaning effect of chemistries. It has also been proven that ultrasonics is the only technique for effective and speedy removal of buffing and polishing compounds from the substrate material. Recognizing the benefits of this technology, chemical manufacturers have developed chemistries specifically for use with ultrasonics.

These chemistries have lower operating temperatures and, in some cases, are pH-neutral. Just as it is beneficial in cleaning, ultrasonics is also beneficial in the rinsing process. This is because most cleaners are a combination of surfactant and cosurfactant that require thorough rinsing to be effective.

In most applications, ultrasonics in the rinses will help to remove trapped chemicals, plating salts, or debris from recesses or blind holes.

What is Ultrasonics?

This fully enclosed, automated ultrasonic cleaning system was designed especially for processing brass components. (Photo courtesy of CAE Blackstone.)Ultrasonics is the science of sound waves above the frequency normally considered audible for humans (above 18 kilohertz). When vibrations at these high frequencies are introduced into liquids, areas of extremely high vacuum and extremely high pressure are generated alternately at any given point in the liquid as the sound waves pass.

This fully enclosed, automated ultrasonic cleaning system was designed especially for processing brass components. (Photo courtesy of CAE Blackstone.)Ultrasonics is the science of sound waves above the frequency normally considered audible for humans (above 18 kilohertz). When vibrations at these high frequencies are introduced into liquids, areas of extremely high vacuum and extremely high pressure are generated alternately at any given point in the liquid as the sound waves pass.

At a point under the influence of a vacuum, the liquid is literally torn apart to create what is called a cavitation bubble. As positive pressure replaces the vacuum that formed the cavitation bubble, the bubble collapses in implosion, resulting in high-pressure shock waves that do the work ascribed to ultrasonics. These energetic disturbances generated by the implosions of countless cavitation bubbles enhance processes by providing microagitation throughout the liquid volume.

In the cleaning portion of the pretreatment process, the goal is to dissolve or displace a contaminant. Solid contaminants (such as buffing or lapping compound and metal fines) are removed first by dissolving whatever “binder” may be present, and then displacing the contaminants far enough from the substrate to break ionic bonds, attracting them to the surface. In all cases, successful contaminant removal requires an exchange of liquid at the contaminant/chemistry interface to replace spent chemistry with fresh chemistry to further the contaminant removal process.

Sufficient liquid exchange may be achieved using conventional techniques when the surfaces to be cleaned are smooth and flat. Blind holes, interior surfaces, and hidden areas (such as found inside a “hem” in a sheet metal part) offer challenges beyond the capability of many conventional techniques. Ultrasonic cavitation is able to penetrate any place where the liquid goes to provide thorough processing in otherwise inaccessible areas.

Ultrasonic Equipment

Ultrasonic cleaning equipment consists of a tank to contain the processing liquid, an ultrasonic transducer to introduce the high-frequency sound vibrations into the liquid, and an ultrasonic generator to provide high-frequency electrical energy to power the ultrasonic transducer.

These building blocks may take a variety of forms, depending on the application and the way parts are processed. In its simplest form, the ultrasonic equipment may consist of a self-contained bench-top unit with parts processed manually through the tank. This type of equipment is common in the jewelry industry.

The next step is a multi-tank console-type system with one or more tanks for ultrasonic cleaning, rinsing, and drying. Decorative hardware would be a good candidate for cleaning in a multi-tank console system.

Large production systems, with up to several thousand gallons of capacity, most often utilize modular-type immersible ultrasonic transducers mounted in otherwise conventional processing tanks, with the ultrasonic generators located in a separate electrical enclosure for protection against potentially hostile environments. Large, high-volume items (such as automotive wheels and bumpers, sanitary and architectural hardware items, etc.) are cleaned in systems of this size.

Selection of Ultrasonic Equipment

In all cases, it is recommended that the potential ultrasonic equipment supplier be directly involved in the specification of equipment, which should include a process evaluation with actual parts cleaning performed by the supplier and a thorough survey of the installation location, including an on-site visit if possible.

A viable equipment proposal will include details on the ultrasonic equipment and how it is to be used in the application. Important considerations for the ultrasonic system include the number and placement of ultrasonic transducers, their frequency and power rating, protection of the transducers and generators against damage, and detailed warranty information.

Once ultrasonic cleaning equipment is in place, maintaining its effectiveness requires attentiveness to a number of process variables, including solution temperature and the elimination of contaminants removed in the cleaning process from the cleaning solution.

System Design

So far, we have discussed the types of contaminants, substrate, chemistry, and ultrasonic technology and equipment. All these factors will determine the specifications for the complete cleaning line. The addition of automation is necessary in most precision cleaning applications where process reliability, consistency, and high-volume throughput are required.

The parts handling system is one of the most important features of the cleaning line. The ability to optimize the cleaning results, minimize handling and parts damage, and maintain high production throughput is strictly dependent on the parts handling system. Energy-absorbing materials (such as polyethylene or fluoropolymers) should not be used for parts fixturing (baskets, etc). The position of the transducers in the tank will affect the ability to maintain the uniformity of the ultrasonic energy. Bottom-mounted transducers are preferred, except in cases where sludge buildup is anticipated on the bottom of the tank, or the ratio of tank depth to width exceeds 1.5 to 1. In these cases, side-mounted transducers give better performance and ultrasonic field uniformity.

As discussed previously, the choice of ultrasonic power needs to be adequate to cavitate the entire volume of liquid with the workload in place. Care needs to be given when increasing the ultrasonic power because of problems associated with cavitation erosion and “burning” on some substrate materials.

The choice of chemistry and the process variables have also been discussed above. The addition of weir, sparger, and filtration increases the life of the bath and improves the overall efficiency of the process. The level of filtration required is dependent on the type of application and the level of cleanliness required. Sufficient rinsing between process steps is necessary to prevent watermarks.

Final rinsing is usually achieved in deionized water in a two- or three-stage cascaded rinse. These rinses usually have fine particle filtration with a continual introduction of fresh, high-purity water in the last rinse. Rinses can be controlled automatically.

Basic Principles

It is almost impossible to design one system to fit every cleaning requirement. Some basic principles have to be followed, however, when designing any cleaning line. Each application or coating process encounters similar problems during and after the cleaning cycle. These problems remain consistent with the variables discussed earlier, such as substrate material, the level and nature of the contamination, and process chemistry. Once resolved, we are left with the basics of equipment design, automation, and parts handling specific to each application.

With a goal or direction in mind and careful consideration of all the variables discussed here, one can successfully integrate the pretreatment line with the finishing application. Although the initial equipment investment can be higher than that of a solvent cleaning system, the investment is often quickly recovered with increased productivity, reduced reject rate, and lowered chemical costs.

The ability to meet and exceed the cleaning requirements of any coating application is a result of careful consideration of all the variables discussed earlier, along with close cooperation between the equipment supplier, chemical supplier, and the customer.

Brian Nevill was product manager for CAE Blackstone Cleaning Technologies in Cincinnati, Ohio, which is now Blackstone-NEY Ultrasonics. After earning a degree in marine science from Liverpool Polytechnic, he entered the surface finishing industry, specializing in vacuum coating processes and electroplating. He has 13 years of experience working with a variety of coating technologies in the aerospace and semiconductor industries. He has also served as the project engineer for the installation of four coating centers in Europe and Asia. Visit https://www.blackstone-ney.com.

References

- John Fuchs, Ultrasonic Cleaning: Fundamental Theory and Application.

- ASM Handbook, Vol. 5, “Surface Engineering.”