Several years ago, when EMI Quality Plating in Evansville, Indiana, was asked by a manufacturer in the aerospace industry to plate some parts for a project they were working on, its owners took a pause before agreeing to work on the parts.

Jake Stocks“My first response was, ‘We won’t do it if we can’t do it right,’” says Jake Stocks, President of EMI. “Less than perfect plating could lead to corrosion, which could weaken the structural integrity and ultimately system failure.”

Jake Stocks“My first response was, ‘We won’t do it if we can’t do it right,’” says Jake Stocks, President of EMI. “Less than perfect plating could lead to corrosion, which could weaken the structural integrity and ultimately system failure.”

Stocks is a pilot himself, which lent credence to his worry about making sure EMI knew what they were doing before taking on aerospace projects. From that day forward, he made sure EMI followed strict quality standards that allowed them to take on parts from the aerospace industry.

“We were able to make the commitment and open new opportunities for EMI,” says Stocks, whose shop specializes in plating processes for air cavity packages, laser components, and barrel plating of plastic components.

New Ownership, New Branding

EMI began in 2005, but it wasn’t until Stocks took ownership in 2016 and rebranded the company with a more modern look and vision moving forward.

“We are spread throughout all industries, which makes us unique,” says Jo’Van Wiggins, EMI’s Chief Operating Officer.

Jo'Van WigginsTheir current focus runs the gamut: military defense, medical, automotive, RF microwave, laser, cellular, consumer electronics, optics, HVAC/refrigeration, computer, aerospace, and telecommunications.

Jo'Van WigginsTheir current focus runs the gamut: military defense, medical, automotive, RF microwave, laser, cellular, consumer electronics, optics, HVAC/refrigeration, computer, aerospace, and telecommunications.

EMI’s top processes are gold plating — both electrolytic and immersion— and electroless gold, silver, nickel (low, mid, and high phosphorus), tin (bright/matte), and copper.

Aside from Stocks and Wiggins, other top company officials include Ann Branson, Chief Financial Officer; Kendra Nance, Quality Manager; and Brian Hatfield, EMI’s Technical Director.

Adding Two New Gold Plating Lines

Stocks says EMI has recently added two dedicated plating lines for gold and an additional building to expand for future plating needs. The facility currently runs two shifts but has been flexible in its scheduling depending on the plating needs of its customers.

EMI operates out of two modern and well-organized buildings. Their shipping and receiving area allows for efficient movement of products and materials in and out of their facility.

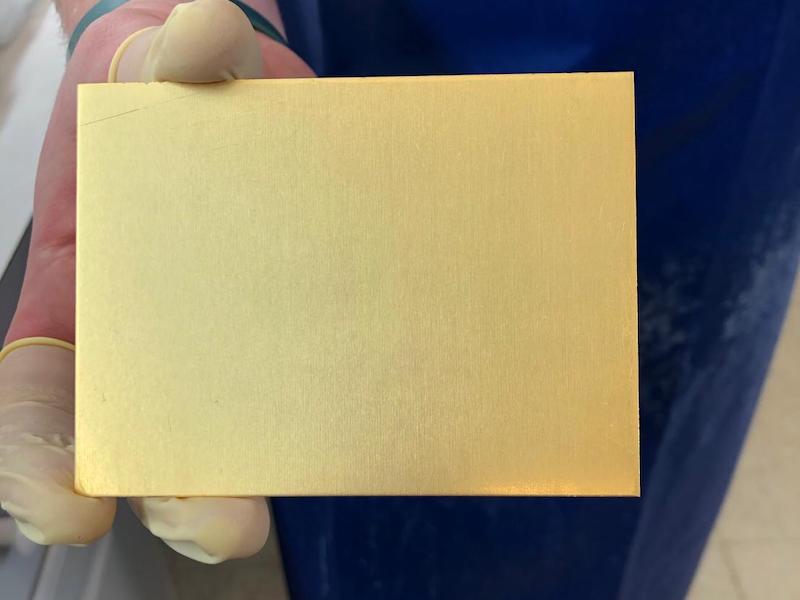

EMI Product Sample“Our customer service is what sets us apart,” Stocks says. “Being a smaller company allows us to personalize services and be there for our customers 24/7. In larger companies, they have a large array of clientele. This allows us to be more personalized with services.”

EMI Product Sample“Our customer service is what sets us apart,” Stocks says. “Being a smaller company allows us to personalize services and be there for our customers 24/7. In larger companies, they have a large array of clientele. This allows us to be more personalized with services.”

Wiggins says that having such a diversity in the industries it serves has allowed EMI to weather storms that other plating facilities may not have been able to navigate.

“The fact that, during these times, our splits in industries allowed us to survive,” Wiggins says. “To make a long story short, our diversification allowed us to focus and increase in certain areas.”

Achieving Environmental Stewardship

EMI can process various substrates, including ABS plastic, copper, steel, aluminum, aluminum-silicon carbide, diamond machined surfaces, metalized ceramic, Kovar, stainless steel, brass, and direct bond copper on ceramic.

Stocks says EMI is committed to conserving valuable natural resources and contributing to the preservation of the environment and operates a newer wastewater treatment system in order to remain in compliance with all regulatory authorities. Twice they have been presented the Environmental Excellence Achievement Award by the Evansville Water & Sewer Utility and the Environmental Management Corporation.

Stocks says EMI is committed to conserving valuable natural resources and contributing to the preservation of the environment and operates a newer wastewater treatment system in order to remain in compliance with all regulatory authorities. Twice they have been presented the Environmental Excellence Achievement Award by the Evansville Water & Sewer Utility and the Environmental Management Corporation.

Stocks says success for EMI will depend on finding innovative technology to provide cost savings to their customers, as well as new opportunities.

“We want to explore industries that are expanding for the future,” he says. “As we grow into a new stage of technology worldwide, we want to provide plating service in that industry. Our plating diversification will provide these services.”

Visit https://emiplating.com/