For some, nothing beats the shine of a fancy new golf putter to grab a person’s attention.

Jo'Van WigginsSo when EMI Quality Plating in Evansville, Indiana, wanted to introduce their new machining division — Dynamic Innovations — in May of 2024, they didn’t market any unique parts or sophisticated complexity to attract potential customers.

Jo'Van WigginsSo when EMI Quality Plating in Evansville, Indiana, wanted to introduce their new machining division — Dynamic Innovations — in May of 2024, they didn’t market any unique parts or sophisticated complexity to attract potential customers.

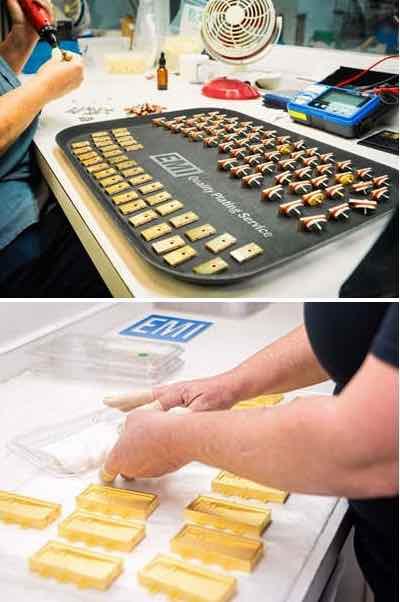

Instead, President Jake Stocks and Chief Operations Officer Jo’Van Wiggins launched a line of golf putters that showcase the craftsmanship and versatility of having a machining operation on one side of the building, and an anodizing and plating operation on the other.

“As we were talking about expanding out the brand, one of the things that we wanted to capture is that we can machine a part and walk it within a couple of feet and start the plating process,” Wiggins says. “Strategically, it keeps the cost low so customers don't ship parts all over the place. We could do everything within our facility and ship it out to the customer directly.”

Growing the 50,000-Square-Foot Business

EMI specializes in silver, gold, and nickel plating, certified welding inspectors, and additional specialty plating processes.It’s a unique idea that Stock and Wiggins came upon as they looked at growing the 50,000-square-foot business that finds itself located smack in the middle of some of the most dense manufacturing operations in the U.S.

EMI specializes in silver, gold, and nickel plating, certified welding inspectors, and additional specialty plating processes.It’s a unique idea that Stock and Wiggins came upon as they looked at growing the 50,000-square-foot business that finds itself located smack in the middle of some of the most dense manufacturing operations in the U.S.

EMI is about 90 minutes from Louisville, Kentucky, less than three hours north of Nashville, Tennessee, just over two hours from St. Louis, Missouri, and also two hours south of Indianapolis.

“ We are in this crazy little pocket near some of the big cities that are close by,” Wiggins says. ”It helps us with the logistics as far as getting product back to customers, which is within one or two days with freight and logistics. Indiana truly is the crossroads of America.”

EMI specializes in silver, gold, and nickel plating, certified welding inspectors, and additional specialty plating processes such as palladium, diamond coatings, and low-, mid and high-phos nickel, as well as electroless nickel.

“We have a lot of choices and options for potential partnerships with different companies,” Wiggins says. “And we are only using about 25,000 square feet, so we're ready to expand and open up. We also have real estate around our facility, so we're able to build on and open up the capacity even more if need be.”

Rebranded With a More Modern Look and Vision

EMI serves various industries, including military defense, medical, automotive, RF microwave, laser, cellular, consumer electronics, optics, HVAC/refrigeration, computer, aerospace, and telecommunications.EMI began in 2005, but it wasn’t until Stocks took ownership in 2016 and rebranded the company with a more modern look and vision. The list of industries they serve is just as voluminous as the number of processes they offer: military defense, medical, automotive, RF microwave, laser, cellular, consumer electronics, optics, HVAC/refrigeration, computer, aerospace, and telecommunications.

EMI serves various industries, including military defense, medical, automotive, RF microwave, laser, cellular, consumer electronics, optics, HVAC/refrigeration, computer, aerospace, and telecommunications.EMI began in 2005, but it wasn’t until Stocks took ownership in 2016 and rebranded the company with a more modern look and vision. The list of industries they serve is just as voluminous as the number of processes they offer: military defense, medical, automotive, RF microwave, laser, cellular, consumer electronics, optics, HVAC/refrigeration, computer, aerospace, and telecommunications.

EMI operates out of two modern and well-organized buildings. Their shipping and receiving area allows for efficient movement of products and materials in and out of their facility.

“Our customer service is what sets us apart,” Stocks says. “Being a smaller company allows us to personalize services and be there for our customers 24/7. In larger companies, they have a diverse client base. This allows us to be more personalized with services.”

Another significant advantage for EMI has been that Stocks is a pilot with his own airplane, enabling the management team to make quick visits to customers and potential customers a few states away. That concierge service even includes delivering parts, if needed.

“It's a selling point in some ways,” Wiggins says. “Jake comes from a family of pilots; even his grandmother was a pilot. It is to our advantage to be able to fly in and see a customer and fly back the same day. Logistically, we've delivered products to customers. That's a great advantage to be able to provide a product that they desperately need for the defense industry or those in the laser or medical industry. That's an advantage that we do have and we enjoy it.”

Partnership with Local Career Center Helps Growth

EMI takes part in WPCC’s annual “Signing Day” in recruiting employees — just like some schools do when high school athletes sign letters-of-intent to attend college. One big reason for EMI Quality Plating’s growth — and that of its Dynamic Innovations machining brand — has been the ability to add to its staffing levels when needed. A huge resource is nearby Warrick Pathways and Career Center in Boonville, Indiana, where junior and senior high school students can enroll to get vocational training.

EMI takes part in WPCC’s annual “Signing Day” in recruiting employees — just like some schools do when high school athletes sign letters-of-intent to attend college. One big reason for EMI Quality Plating’s growth — and that of its Dynamic Innovations machining brand — has been the ability to add to its staffing levels when needed. A huge resource is nearby Warrick Pathways and Career Center in Boonville, Indiana, where junior and senior high school students can enroll to get vocational training.

The Advanced Manufacturing program trains students in Precision Machining and Industrial Maintenance, enabling EMI to recruit workers for both its plating operation and its new machining division.

EMI takes part in WPCC’s annual “Signing Day” in recruiting employees — just like some schools do when high school athletes sign letters-of-intent to attend college. It’s all part of Wiggins and Stocks’ plan to make working in the finishing and machining industry more attractive to students graduating from vocational training programs.

“Right now we're going through a situation where we have to rebrand as far as employees go and get new people and new talent,” Wiggins says. “You don't see a lot of people in this industry like you used to, and the strategic plan that we've executed was to partner with a local trade school. It has helped us out as well because we were able to get high school students who worked here as interns, and when they graduated from high school, we hired them full-time. We're not getting any younger, and we're able to start training these younger people in and get them familiar with us as well. It’s been great.”

Much of that perspective comes from Wiggins having worked outside of the industry finishing market for many years before joining EMI more than 10 years ago. He came from a background in hospitality, working for Marriott hotels in Indianapolis before moving to Evansville. Wiggins began working in outside sales for EMI and was eventually hired full-time to run the quality department.

He was promoted to Chief Operations Officer about nine years ago.

“ I learned the hard knocks up to the top,” Wiggins says. “I believe that you have to start at the base level of metal finishing — or in your career in general — to gain that respect from employees. I would never have them do something that I haven't done before. I've worked until 3, 4, 5 a.m., and I’ve come in at crazy times. I've worked in every different department. I know how to make a good part, how to make a bad part, and those things are very valuable as you navigate through this industry.”

The idea to start Dynamic Innovations came about as Stocks is an engineer by training and has extensive experience in CNC machining. His father owned a die-casting company, so Stock’s experience with that side of manufacturing has been ingrained in him.

He continued dabbling in machining as a hobby until one day he told Wiggins that they should add the service for their customers who needed it. The idea was to start with the golf putters and see where that took them.

“ We started machining putters, and we were doing some other side jobs and assisting some machine shops on some work when they've reached capacity,” Wiggins says. “We got into this lane of golf putters and what started to be just a hobby and, ‘Let's just see what we can do,’ and put feelers out there in the industry turned out to be something pretty good.”

Golf Putter Business Tees Off

Wiggins promotes the new golf putters by delivering them to such notabls as Notre Dame football coach Marcus Freeman.The golf putter business, meanwhile, has taken off somewhat. EMI experimented with different finishes and experimented with high-level gold putters all the way down to bright nickels, and the company showcased them in various locations, such as local golf courses and golf stores.

Wiggins promotes the new golf putters by delivering them to such notabls as Notre Dame football coach Marcus Freeman.The golf putter business, meanwhile, has taken off somewhat. EMI experimented with different finishes and experimented with high-level gold putters all the way down to bright nickels, and the company showcased them in various locations, such as local golf courses and golf stores.

“That helped with our brand to expand out a little bit strategically,” Wiggins says. “Obviously, for 2025, the tariffs scared the industry off a little bit, so we're just looking at ways to get a small percentage of what is out there in the industry. So far, we've been successful.”

For EMI Quality Plating’s growth plan, Wiggins says diversification is still the key. When he first began at the company, they were heavy on automotive. When that work began to head south to Mexico, Wiggins and Stocks knew they had to have a Plan B to keep the company profitable.

That idea was to strategically go after a percentage of each industry they were working in at the time.

“That way, if one thing falls, we can pivot to another industry,” Wiggins says. “That's been good for us, and our customers have done a great job at giving us new business by saying to others, ‘These are components that we have finished at EMI plating, and you’ve got to try them out.’ Our customers have been our biggest sales managers we've had out there, and that speaks volumes about some of our work.”

Plant Engineer Ryan McGehee has been instrumental in getting the machining operations up and running, and oversees the products of the putters.

Adding Laser Engraving and Zinc Plating

EMI has recently invested in new metal laser engraving equipment to meet the finishing needs of some customers, and they have also added zinc plating capabilities.

“ We are always R&Ding things, and just staying ahead of what's out there right now in the market,” Wiggins says. “We would like to add that to our services and what we can now do at our facilities.”

Stocks says success for EMI will depend on finding innovative technology to provide cost savings to their customers, as well as new opportunities.

“We want to explore industries that are expanding for the future,” he says. “As we grow into a new stage of technology worldwide, we want to provide plating service in that industry. Our plating diversification will provide these services.”

Visit https://emiplating.com.