When a fire strikes a metal finishing facility, the devastation goes far beyond damaged equipment and scorched infrastructure.

It impacts customer relationships, halts production, and initiates a complex dance with insurance providers, regulatory agencies, and supply chain partners—all while the clock ticks on rebuild timelines and client retention.

In this new monthly column, we’ll walk through the process of fire remediation from the perspective of a real-world case: Elite Metal Finishing. This Southern California-based shop suffered a catastrophic fire in July 2025.

As a long-time plating industry veteran and President of Ronatec, Jim Wetherald was brought in as a consultant to lead Elite’s President Dan Rose through the rebuild process—working directly with the insurance carrier, managing engineering evaluations, and ultimately coordinating the design and fabrication of the replacement line.

“Your Building is On Fire”

From Dan Rose, President of Elite Metal Finishing

Dan RoseIt’s 9:45 pm on Tuesday, July 1, and I’m on a holiday week getaway with my wife just south of Santa Barbara, California.

Dan RoseIt’s 9:45 pm on Tuesday, July 1, and I’m on a holiday week getaway with my wife just south of Santa Barbara, California.

We are sitting on the patio after dinner, chatting, enjoying a few glasses of wine, when my phone rings; it is a customer who occupies the building across the street.

“Dan, your building is on fire,” I heard him yell into the phone,

In disbelief and shock, I called our General Manager, Sue, to get more information, hoping that no one was hurt and to learn the extent of the damage. It’s under control, I’m told, and no one was injured, so thank God.

The four-hour drive the next morning through L.A. traffic was bad enough, but the thought of the unknown and what lies ahead was more than grueling.

The questions came hard and fast: What caused it? Is everyone safe? What’s salvageable? How do I tell my employees? What about our customers?

When a fire breaks out in a business, the public usually sees the aftermath in photos: charred walls, collapsed roofs, firefighters in reflective gear, and maybe a few quotes about insurance and rebuilding. What’s often missing from the story is the emotional wreckage left behind—the invisible, smoldering grief of the owner.

For most entrepreneurs, a business is more than a livelihood. It’s a life’s work. It’s where dreams are built, risks are taken, and identities are forged. When a fire happens, it doesn’t just destroy physical assets—it strikes at the heart of who they are.

In the early hours after the fire, I felt a strange numbness. Owners might stare at the ruins in disbelief, caught between trying to process the facts and fighting off panic; it’s surreal. One moment, you’re managing your business, checking on production, planning growth —and the next, you’re standing behind yellow tape watching smoke rise from everything you’ve built.

The questions came hard and fast: What caused it? Is everyone safe? What’s salvageable? How do I tell my employees? What about our customers? But beneath those practical concerns is an overwhelming feeling of helplessness. There’s no playbook for this kind of loss.

If there’s any solace to be found, it’s in the resilience of community and the generosity of others. Employees rally. Customers send messages of support. Competitors offer help. These acts remind business owners they’re not alone.

Even when the fire is accidental or beyond one’s control, you feel a deep sense of guilt: Could I have prevented this? Did I overlook a risk? And worse—Have I let my team down?

Once the immediate crisis was over, the next stage kicked in, filled with sleepless nights and anxiety. Insurance claims, temporary closures, vendor negotiations, and keeping employees afloat—all while managing personal emotions—created a brutal mental load.

There’s also the quiet fear that rarely gets voiced: Will we recover? Will we reopen? Or is this the end?

That was an easy answer. Giving up is not in my DNA, and I refuse to let this fire beat us. We will rebuild bigger and better.

If there’s any solace to be found, it’s in the resilience of community and the generosity of others. Employees rally. Customers send messages of support. Competitors offer help. These acts remind business owners they’re not alone.

I am deeply grateful to Ronatec and Miles Chemical for stepping up and partnering with us; Miles for guiding me through the remediation process and chemical removal, and Ronatec for coordinating all aspects of designing and installing new plating lines. Additionally, Jim Wetherald met with the insurance adjusters, educating them on the process of building new plating lines.

Also: Hixson Metal Finishing, All Metals Processing, Elite Metal Finishing LLC, Aircraft X-Ray, and DMC for offering their assistance with the rebuilding process.

I hired Gary Baca, President of Counterpoint Public Adjusters, to negotiate on my behalf with the insurance company. This is instrumental in ensuring we receive what is needed to rebuild the shop and be operational as soon as possible.

The Rebuilding Process

From James Wetherald, President of Ronatec

Jim WetheraldThe Situation

Jim WetheraldThe Situation

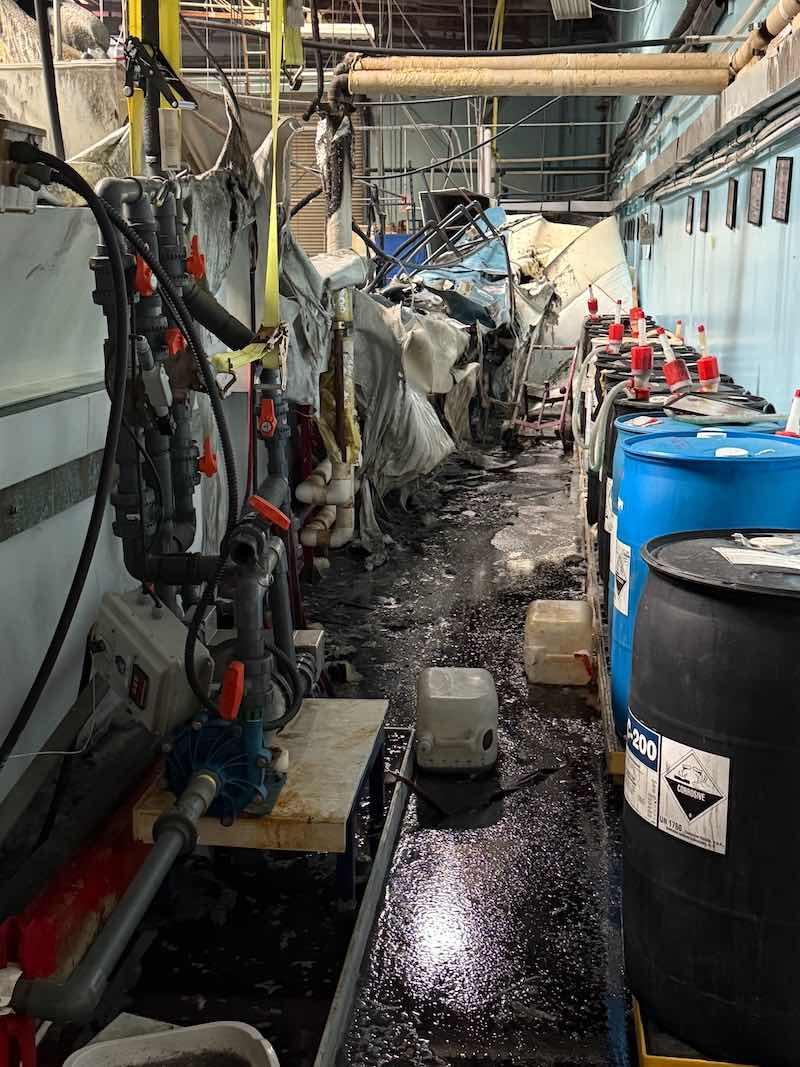

The fire at Elite Metal Finishing caused extensive damage to their anodizing and plating lines, electrical infrastructure, and ventilation systems (can we say how much or what % is operable?). While no one was injured, the damage rendered key production areas inoperable and triggered an immediate shutdown.

Our initial priorities were clear:

- Secure the site and perform structural safety inspections.

- Begin forensic analysis to determine the fire’s cause and the full scope of damage.

- Preserve any salvageable equipment while documenting all losses with meticulous accuracy for the insurance claim.

- Establish temporary workarounds to maintain partial operations where possible.

This wasn’t just about cleanup—it was about preserving Elite’s customer base and positioning the business for a more modern, efficient rebuild.

What We’ve Done So Far

Since being brought in, our team has:

- Coordinated with structural engineers, fire marshals, and environmental agencies.

- Partnered with Elite’s legal, Public Adjuster (Gary Baca), and accounting teams to compile a comprehensive business interruption claim.

- Built detailed replacement cost estimates/matrices for each affected line, tank, ventilation system, and process station—including material, labor, freight, and schedule impacts.

- Held multiple on-site negotiations with the insurance adjuster to ensure realistic, industry-specific valuations were applied.

Where We Stand Now

At this stage, we’ve made significant progress—but this will be a long and detailed process. We’ve completed the initial assessments, engaged with insurance adjusters, and provided a full accounting of damages supported by technical documentation and replacement cost modeling.

We’re now entering the more complex phase: negotiating and securing staged approvals from the insurance carrier. These negotiations are ongoing and will likely span several months, as each line item is reviewed, challenged, and—eventually—funded.

In the meantime, we’ve begun preliminary design and engineering work for the replacement plating and anodizing systems. While we can’t start fabrication in earnest until funding is approved, early-stage planning is crucial to compress the rebuild timeline once we get the green light.

Over the coming months, we’ll use this column to share lessons learned, critical missteps to avoid, and strategies for managing a disaster recovery effort in an industry where downtime is devastating—and precision matters. We will report back on the progress.

Visit https://www.elite-metalfinishing.com and https://ronatec.us.