James Lindsay, Ph. D., is a retired research engineer from General Motors who has volunteered for numerous surface finishing industry groups over the past several decades.

Dr. Lindsay received the National Association for Surface Finishing Presidential Award at the organization’s 2018 Sur/Fin conference for his years of contribution to the finishing industry and to the various organizations that support the industry.

Dr. Lindsay was honored for his many years of service to the NASF and AESF as technical editor of their scientific papers and research. He was previously editor of the NASF’s in-house publications and worked for General Motors until retiring from the company.

From the 1996 Blum Award:

Dr. James H. Lindsay was announced as the 1996 recipient of AESF's Scientific Achievement Award.At this year's SUR/FIN banquet in Cleveland, attendees applauded and cheered when Dr. James H. Lindsay was announced as the 1996 recipient of AESF's Scientific Achievement Award. Well-known throughout the Society and the industry for his easygoing manner and cheerful approach to any situation, Dr. Lindsay was nominated by the Detroit Branch for his many accomplishments as a research professional, as well as for his years of dedication to the AESF and to the advancement of surface finishing in the automotive industry.

Dr. James H. Lindsay was announced as the 1996 recipient of AESF's Scientific Achievement Award.At this year's SUR/FIN banquet in Cleveland, attendees applauded and cheered when Dr. James H. Lindsay was announced as the 1996 recipient of AESF's Scientific Achievement Award. Well-known throughout the Society and the industry for his easygoing manner and cheerful approach to any situation, Dr. Lindsay was nominated by the Detroit Branch for his many accomplishments as a research professional, as well as for his years of dedication to the AESF and to the advancement of surface finishing in the automotive industry.

Dr. Lindsay (and his father before him) may have had more influence on the function of the automobiles in your life—even if they have not all been General Motors products—than you could realize. Learning more about Dr. Lindsay and the accomplishments that have made him a well-deserving recipient of the AESF's most prestigious award, it is interesting to understand his family background.

Like Father, Like Son

Many fathers dream that their sons will follow in their footsteps. The senior James H. Lindsay was an excellent role model. He was a plating engineer for his long career at General Motors (GM) in Detroit and Flint, MI. His efforts focused on the improved performance of chromium deposits for decorative trim. He was involved with initial research into micro-cracked chromium deposits and was closely associated with the development of the CASS test. He was also the author or co-author of several papers on plating.

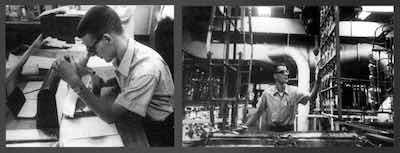

Dr. Lindsay in his days as a General Motors enginer.A true professional who believed in the importance of technical associations, the elder Lindsay was a key member of the then-AES Detroit Branch. As an AES national president in 1969-70, one of his major efforts was to strengthen the Society's international membership and increase its international ties. In this respect, he was highly involved with developing the Australasian Institute of Metal Finishing. Upon retirement, he was widely respected as the technical editor of the AES journal (then known as Plating), serving from March 1974 through January 1977. A National Honorary Member, he died in 1980.

Dr. Lindsay in his days as a General Motors enginer.A true professional who believed in the importance of technical associations, the elder Lindsay was a key member of the then-AES Detroit Branch. As an AES national president in 1969-70, one of his major efforts was to strengthen the Society's international membership and increase its international ties. In this respect, he was highly involved with developing the Australasian Institute of Metal Finishing. Upon retirement, he was widely respected as the technical editor of the AES journal (then known as Plating), serving from March 1974 through January 1977. A National Honorary Member, he died in 1980.

There are many parallels in the lives of the Lindsay father-son team. As a teenager, the young Jim Lindsay had a vague awareness of his father's work, but it was an actual plating demonstration by his chemistry teacher that made everything click. He decided on a career in the plating industry. Then, like his father, Jim joined General Motors immediately upon graduation from high school, when he started his undergraduate program at GM Institute (A graduate of the Institute with a bachelor's in mechanical engineering, Jim also holds a master's in materials engineering from Rensselaer Polytechnic Institute and a Ph.D. in metallurgy from The Pennsylvania State University.). His continuing career covers more than 30 years of significant research and development in plating systems, with important contributions to GM and the entire finishing industry.

Dr. Lindsay at GM.A staff research engineer with GM Research and Development Center, his research is in the area of advanced surface coatings - electroplated plastics, functional vacuum deposits, electrodeposition on aluminum for wear and decorative applications, high-speed electroplating and electroforming and electrogalvanized and related coatings for sheet steel.

Dr. Lindsay at GM.A staff research engineer with GM Research and Development Center, his research is in the area of advanced surface coatings - electroplated plastics, functional vacuum deposits, electrodeposition on aluminum for wear and decorative applications, high-speed electroplating and electroforming and electrogalvanized and related coatings for sheet steel.

In his career with the company, Dr. Lindsay was involved with process engineering (production electroplating, die-casting, and heat-treating) at the world's largest decorative plating facility, The Ternstedt Division of GM in Flint, MI. Then, in 1969, he accepted a research position as a technical staff member at Bell Laboratories, where he worked on developing coating processes in sputtering and vacuum deposition for novel electrical contact surfaces.

From 1972 until he rejoined GM in 1977, Dr. Lindsay was a research professional for Udylite Corporation, working with proprietary plating and surface finishing processes and equipment. While at Udylite, he developed a flow cell design for continuous plating of a ternary-bearing alloy and special flow cells for copper electrowinning. He also researched electrodeposited CrOx and NiOx deposits for solar energy applications.

Jim also shares his father's dedication to the AESF, having joined the Society in 1964 as a member of the Saginaw Valley Branch. He became affiliated with the Detroit Branch in 1977, served on the Branch Board of Managers, and was Branch president from 1985-86. In addition, Jim continues to be active on the national level, serving on AESF's Research Board, the Technical Education Board, and the Publications Board.

A prolific author (a complete listing of his numerous published works would encompass several pages), he's also written and reviewed lectures in the Society's Illustrated Lecture series. He is currently a contributing technical editor to Plating and Surface Finishing (P&SF). In 1990, he received P&SF's Silver Medal and an Outstanding Paper award for "The Interaction Between Electrogalvanized Zinc Deposit Structure and the Forming Properties of Sheet Steel."

Map in Dr. Lindsay's home with the blue showing U.S. highways he has driven, and the red for flights to cities.

Map in Dr. Lindsay's home with the blue showing U.S. highways he has driven, and the red for flights to cities.

Summary of Accomplishments

In addition to holding five U.S. patents, Dr. Lindsay's many industry-related accomplishments include:

- Graduate work shed light on the effect of hydrogen evolution on cobalt - important information during the nickel shortage of the early 1970s when cobalt was touted as a substitute for nickel in copper-nickel-chromium systems.

- Developed a process and plating cell for the continuous plating of a Babbitt alloy for engineering bearings.

- Studied the effect of high-speed solution flow on the product and economics of copper electrowinning.

- Early work involves using nickel underlayers in nickel-black chromium systems for solar energy applications.

- Developed an alternative to the chemical preplate process for plated plastics, based on vacuum technology - philosophy involved the best of both vacuum and plating technologies; developed a process for ABS, ABS alloys, and mineral-filled nylon resins.

- Developed an understanding of the relation between surface roughness and drawing performance of stamping dies plated with engineered chromium.Results indicated high friction is found when the plated surface is too rough and smooth.

- Undertook a comprehensive study of the changes encountered by the manufacturing process with the introduction of zinc electro-galvanized sheet steel in automotive body panels.Developed an understanding of the effect of operating conditions on crystal orientation and coating orientation on the various manufacturing processes, including stamping, spot welding, phosphating, and painting.

- Developed proprietary processes for wear- and friction-reduction coatings in various automotive applications.

Although quiet and soft-spoken, Jim has a solid reputation for knowledge of the finishing industry and plating systems. His love of travel has made him a willing and excellent ambassador for GM, the finishing industry, and the AESF all over the U.S., Japan, and Australia. This abbreviated look at the 1996 Scientific Achievement Award recipient's accomplishments illustrates why he stands out in the industry.