Chemcoaters in Gary, Indiana, has engineered a new acrylic coating for galvanized steel to better serve OEMs and steel providers.

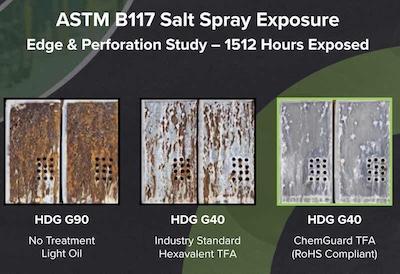

ChemGuard Thin-Film Acrylic (TFA) substantially increases the longevity of metal products by protecting against corrosion. It combines technology from the company’s traditional InterCoat ChemGuard portfolio with properties commonly found in acrylic-heavy coating systems to create an innovative, durable, and aesthetically pleasing metal coating solution.

“When our customers source acrylic coatings, they have to sacrifice functionality and anti-corrosion performance in the name of visual aesthetics. ChemGuard TFA means they no longer have to,” says Brit Capizzano, R&D director at Chemcoaters. “After extensive trialing and internal testing, we are extremely proud of the resulting product’s exceptional form and function. This coating system being Restriction of Hazardous Substances-compliant (RoHS) makes it even more unique.”

“When our customers source acrylic coatings, they have to sacrifice functionality and anti-corrosion performance in the name of visual aesthetics. ChemGuard TFA means they no longer have to,” says Brit Capizzano, R&D director at Chemcoaters. “After extensive trialing and internal testing, we are extremely proud of the resulting product’s exceptional form and function. This coating system being Restriction of Hazardous Substances-compliant (RoHS) makes it even more unique.”

ChemGuard TFA provides enhanced corrosion protection and is both dry-formable and weldable. The acrylic coating offers anti-fingerprint properties with a bright finish, desirable to many companies seeking acrylic coatings. The coating’s InterReactive technology also offers cutting-edge protection and self-healing properties while ensuring the acrylic cures with a thin, clear finish.

“ChemGuard TFA is unlike any other acrylic on the market,” Capizzano says. “Its ability to enhance product life beyond current industry standards significantly differentiates it, and we’re excited to see how its capabilities will support our customers.”

Chemcoaters intends to offer the new coating to strip and tube mills, steel service centers, and OEMs. This coating is available for application at Chemcoaters’ line in Gary or via chemical wholesale. Interested companies should contact Chemcoaters for wholesale pricing on chemicals.

In addition to their product development efforts, Chemcoaters is one of the largest-capacity steel coating and cleaning locations in the United States, with the ability to process metal sheets ranging from 0.01” to 0.125” thick and 20” to 72” wide. The company also cleans and treats steel, aluminum, and specialty non-ferrous materials, such as zinc strip. Their other capabilities include applying corrosion-inhibiting coatings developed in-house, dry film lube application, TFAs, passivation, metal reclamation, and more.

About Chemcoaters

Chemcoaters is a solutions provider that supplies customers with environmentally friendly, innovative, and quality-driven steel coatings, processes, and services. As one of the largest-capacity steel coating and cleaning facilities in the US, Chemcoaters can clean and treat a wide variety of metal sheet types, as well as apply in-house developed corrosion-inhibiting coatings, dry film lubricants, TFAS, passivation, metal reclamation, and more. Chemcoaters is an ISO 9001-certified business offering state-of-the-art solutions to lengthen the life of steel products.

Visit www.chemcoaters.com.