Ashley and Jason Hunsaker spent a considerable amount of time developing their trademark thermal spray coating, BTHC-0005, which they claim is superior to hard chrome deposits for corrosion protection.

However, the owners of HTS Coatings in Madison, Illinois, didn’t spend much time deliberating over what to call their specially formulated cermet alloy, designed as an alternative to hard chrome plating.

“We call it BTHC because it is ‘better than hard chrome,’” says Ashley, the Chief Executive Officer for the company located just outside the St. Louis area.

Manufacturers Seeking a Suitable Cr6 Replacement

Jason and Ashley Hunsaker started HTS Coatings in 2015 offering thermal spray, machining, grinding, and welding services.While hard chrome plating utilizes chromium in the hexavalent state (hex-Cr), a known carcinogen that the U.S. Environmental Protection Agency has targeted for decades, original equipment manufacturers have sought a suitable replacement that can provide the same, if not better, wear and corrosion resistance.

Jason and Ashley Hunsaker started HTS Coatings in 2015 offering thermal spray, machining, grinding, and welding services.While hard chrome plating utilizes chromium in the hexavalent state (hex-Cr), a known carcinogen that the U.S. Environmental Protection Agency has targeted for decades, original equipment manufacturers have sought a suitable replacement that can provide the same, if not better, wear and corrosion resistance.

“We know that the chrome replacement is coming,” she says. “And we do believe thermal spray is a viable option.”

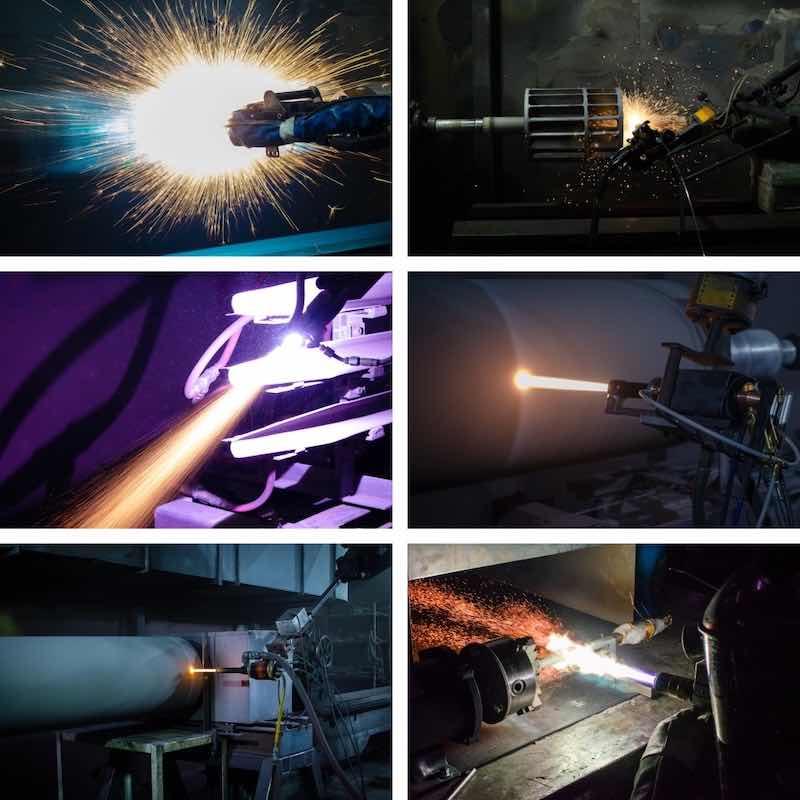

HTS Coatings offers several types of thermal sprays — a process that heats or melts metallic or ceramic materials and deposits them onto a surface — depending on the substrate and corrosion resistance:

- High-Velocity Air Fuel Thermal Spray

- High-Velocity Oxy-Fuel Thermal Spray

- Spray and Fuse Thermal Spray

- Plasma Thermal Spray

- Arc Thermal Spray

- Flame Thermal Spray

The thermal coating application processes — although traced to the 1940s — advanced greatly with the high velocity sprays in the 1980’s. This process uses internal combustion, much like a rocket jet, to generate supersonic gas velocities of approximately 1100 meters/second, generally in the range of Mach 3-4, according to some research.

Educating Customers on the Benefits of Alternative

HTS Coatings offers several types of thermal sprays, a process that heats or melts metallic or ceramic materials and deposits them onto a surface.HTS says their BTHC-0005 tested well with a few of their customers as they work to educate them on the benefits of the alternative to having chrome-plated parts.

HTS Coatings offers several types of thermal sprays, a process that heats or melts metallic or ceramic materials and deposits them onto a surface.HTS says their BTHC-0005 tested well with a few of their customers as they work to educate them on the benefits of the alternative to having chrome-plated parts.

One customer was hydraulically pressing a very abrasive material into a shell and allowed HTS Coatings to spray the inside of the shell to compare its performance with that of the hard chrome they had been using.

“In comparison to chrome, they would get about 3,000 presses in their manufacturing process,” Hunsaker says. “Today, there are over 18,000 presses now with our coating. Not only are we replacing an environmentally damaging material, but we're also offering a solution that will last sometimes eight times longer than chrome plating.”

She says there are limitations to the thermal spray; inside diameters are an issue when it is less than four inches on a part — “We just can’t get in there,” Ashley says — and in areas where the coating area may be very small or hidden inside. There are some equipment developments allowing for down to 2.5” bore so technology keeps advancing.

“We do have limitations,” she says. “If you're getting something dipped in a teeny, tiny little area, there might be some other options. I think that's why chrome has not gone away because they can't find anything that will finish that hole.”

Finisher, Machining, And Grinding Facility

The thermal coating application process can be traced to the 1940s.For now, HTS Coatings is expanding and growing not only as a coating shop but also as a machining and grinding facility. They market themselves as a full-service thermal spray, grinding, machining, and welding facility that specializes in preventing wear from corrosion and erosion, as well as repairing components damaged during operation.

The thermal coating application process can be traced to the 1940s.For now, HTS Coatings is expanding and growing not only as a coating shop but also as a machining and grinding facility. They market themselves as a full-service thermal spray, grinding, machining, and welding facility that specializes in preventing wear from corrosion and erosion, as well as repairing components damaged during operation.

Ashley says many of their customers are in the general industrial, power generation, oil and gas, and transportation sectors. The company has come a long way from its humble beginnings 10 years ago when Jason found out that the St. Louis area metalizing company where he had worked for 17 years was being closed.

He joined several of his former co-workers from the previous position to form HB Coatings in 2015. They operated out of a 30,000-square-foot facility, offering thermal spray, machining, grinding, and welding capabilities using some of the equipment they had purchased at an auction from their previous employer.

“We're not a fabrication shop; we're doing exotic Stellite and Colmonoy, as well as the unusual weld overlays. We're just so different from anything that I've ever really seen.”

“ I was pregnant, and he came home from work and said, ‘Let's do this,’” Ashley recalls. “I said sure; it was pregnancy brain, but it was ‘Let's do it.’”

The Hunsaker’s cashed out their 401K savings — “We laid it literally all on the line,” she says — and got a small business loan to buy the equipment. Almost overnight, they were business owners.

Becoming Sole Owners Brings Challenges

Inner-diameter thermal spray coating is applied.Business came fast for the new company, but also so did the growing pains associated with the pressures of starting a business. Two years later, in 2017, they acquired their partners’ shares and renamed the company HTS Coatings.

Inner-diameter thermal spray coating is applied.Business came fast for the new company, but also so did the growing pains associated with the pressures of starting a business. Two years later, in 2017, they acquired their partners’ shares and renamed the company HTS Coatings.

Jason was the person overseeing shop floor operations, and Ashley, who holds an accounting degree and extensive experience in managing the business side at previous companies, was tasked with managing the office and marketing the company.

Working in a manufacturing facility was something that she was used to doing, and it complemented Jason’s hands-on duties as company president. In college, Ashley worked at a headlight manufacturer on the third shift and often would propose process improvements to save time and money for the company.

“I'd never read anything on lean manufacturing,” Ashley says. “But I said, ‘If we do this and if we had erasers right here, we could cut this off a lot quicker.’ And looking back on that, it was preparing me for things in the future that I just didn't know about.”

“If they want to get a part machined, we can do that in-house, and we can spray it, we can grind it, or we can weld overlay it, and then we can grind it as well.”

She worked in accounting for a Ford dealership and for an interior designer, whom she says taught her a great deal about inventory controls. She was working as a controller for a sister company of Jason’s employer at the time he lost his position and left that position to help him start the new company.

“All of these experiences brought me here to HTS,” says Ashley, who was instrumental in working on getting start-up loans for the new company thanks to her skills in financials and projections.

Big Demand For Plasma Transferred Arc Welding

Many of HTS customers are in the general industrial, power generation, oil and gas, and transportation sectors.On the welding side of the business, HTS is seeing an increased demand for plasma-transferred arc welding (PTAW), a form of hard face welding that utilizes a tungsten electrode and the workpiece as the anode to create and transfer a plasma arc within a stream of ionized gas. This reaction creates heat and a plasma state that can melt and apply metallic materials to other metal surfaces at a temperature of 23,000°F. The heat energy of the constricted arc creates deeper weld penetration in a narrower field. This reduces the heat-affected zone, increases the welding speed over TIG and MIG, and creates an incredibly stable arc for precise surface coatings.

Many of HTS customers are in the general industrial, power generation, oil and gas, and transportation sectors.On the welding side of the business, HTS is seeing an increased demand for plasma-transferred arc welding (PTAW), a form of hard face welding that utilizes a tungsten electrode and the workpiece as the anode to create and transfer a plasma arc within a stream of ionized gas. This reaction creates heat and a plasma state that can melt and apply metallic materials to other metal surfaces at a temperature of 23,000°F. The heat energy of the constricted arc creates deeper weld penetration in a narrower field. This reduces the heat-affected zone, increases the welding speed over TIG and MIG, and creates an incredibly stable arc for precise surface coatings.

“We are really training up our guys on that, and we just got some certifications, too,” Ashley says. “We're working on getting about three more weld certifications. We're not a fabrication shop; we're doing exotic Stellite and Colmonoy, as well as the unusual weld overlays. We're just so different from anything that I've ever really seen.”

The ultimate goal for the company, with its unique ability to weld, grind, and finish parts, is to become a one-stop option for many manufacturers.

“If they want to get a part machined, we can do that in-house, and we can spray it, we can grind it, or we can weld overlay it, and then we can grind it as well,” Ashley says. “We're always looking at how to increase our capacity to be our customer's one-stop shop. We like to say we offer large company capabilities with small company care.”

“ Jason's an engineer, and I'm an accountant by trade, so we are not executives.”

With seven robotically controlled spray booths, Jason and Ashley aim to position HTS Coatings as a leader in the thermal spray industry, believing that offering a range of services will help them achieve this goal.

And part of that is sometimes having to explain to customers all that they can offer them with having so many vertical services under one roof.

“We ask the customer, ‘What is your problem?’ and then we'll work backward,” Ashley says. “It's like algebra: here's the solution, and how did we get there? Let's get you to that solution.”

Turbine blades that have been thermal sprayed.

Turbine blades that have been thermal sprayed.

Unleashing the ‘Mad Scientists’ on Customers

HTS performs extensive training with its team at its Madison, Illinois, facility.It also helps that HTS has a team of engineers who, Ashley says, will sit and brainstorm with a customer to develop a unique solution that may include one or more of the welding, grinding, and finishing processes.

HTS performs extensive training with its team at its Madison, Illinois, facility.It also helps that HTS has a team of engineers who, Ashley says, will sit and brainstorm with a customer to develop a unique solution that may include one or more of the welding, grinding, and finishing processes.

“I call them the mad scientists,” she says. “They love to mix the metals and do all sorts of fun things to get to a solution.”

For Ashley and Jason, they have relied on their faith in growing the business. They have also relied heavily on a Christian business networking group called C12, which helps business leaders achieve company growth through a network of peers.

C12 says it “helps CEOs and executives of growth-stage companies calibrate the entirety of their businesses through our signature 5-Point Alignment Matrix—continually evaluating and aligning revenue growth strategies, financial stewardship, cultural development, and operations within a framework of Business as a Ministry (BaaM).”

“It’s about focusing on the customers that are bringing us repeat business, and how can we service them more.”

The Hunsakers say the networking group has been a huge asset to their company's management and growth.

“ Jason's an engineer, and I'm an accountant by trade, so we are not executives,” Ashley says. “I did not grow up in an entrepreneur home; my dad was an engineer, and my mom was a stay-at-home mom. I didn't see this model for me, and I don't know what it means to be a small business owner.”

Looking for Ways to Add to Services

The Hunsakers say the networking group has been a huge asset to their company's management and growth.However, the C12 group has helped, as have numerous trade associations to which the Hunsakers have signed up HTS Coatings. Combined, it has helped them get the company up and running, and they are always looking for ways to enhance their services.

The Hunsakers say the networking group has been a huge asset to their company's management and growth.However, the C12 group has helped, as have numerous trade associations to which the Hunsakers have signed up HTS Coatings. Combined, it has helped them get the company up and running, and they are always looking for ways to enhance their services.

“ Jason is the visionary who will say, ‘Let's invest,’ and had the idea to invest in the HVAF system,” Ashley says. “And I am the integrator with boots on the ground. I say, ‘Let's write POs, and let's make sure our costs are correct.’”

But at the end of the day, the Hunsakers know that treating customers right and delivering a high level of service will keep those customers coming back and help grow HTS Coatings.

“It’s about focusing on the customers that are bringing us repeat business, and how can we service them more,” Ashley says. “It’s a strategy for us that works. We're still working on that, and we know that we can't be everything to everyone, but it’s about doing our best to be the best for our customers.”

Visit https://htscoatings.com