For over six years, Doug Orantes was president of an electroplating and anodizing shop that didn’t exist anywhere except in his mind. But that wasn’t for a lack of trying.

Doug Orantes and his wife, Loida, look over job orders.Since 2017, Orantes and his wife have been trying to get Aero Plating in Lancaster, California, off the ground. Still, a miscommunication with local city officials derailed those plans until he was finally able to realize his dream of opening the doors in 2023.

Doug Orantes and his wife, Loida, look over job orders.Since 2017, Orantes and his wife have been trying to get Aero Plating in Lancaster, California, off the ground. Still, a miscommunication with local city officials derailed those plans until he was finally able to realize his dream of opening the doors in 2023.

“It’s been a long wait,” Orantes says. “But it has been very much worth it.”

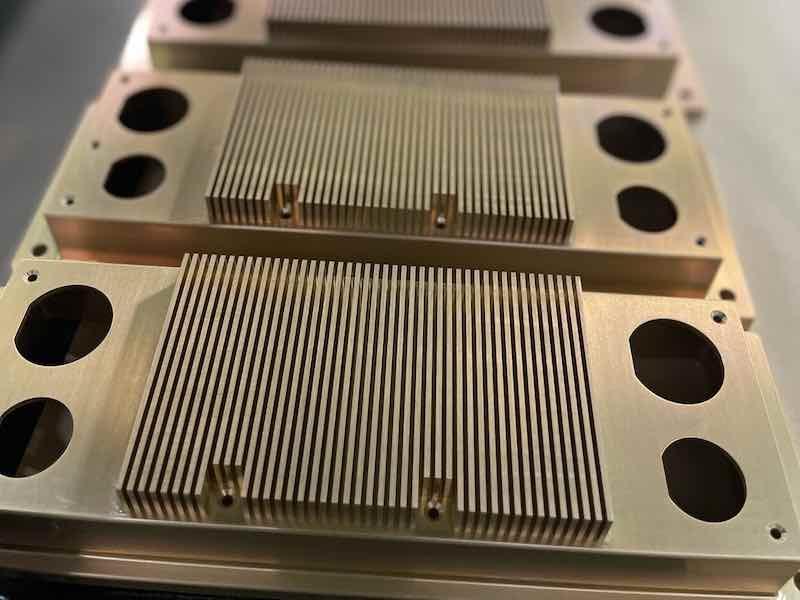

Today, Aero Plating operates in an 8,500-square-foot facility that is certified to 9001:2015/AS9100D and Nadcap standards for chem-film and passivation applications.

The facility offers chemical conversion coating (MIL-DTL-5541, TY I and II CL 1A and CL 3), passivate (AMS2700 Method 1-2), sulfuric anodize (MIL-A-8625, TY II, CL 1), sulfuric anodize dyed (MIL-A-8625, TY II, CL 1), hard anodize (MIL-A-8625, TY III, CL 1), hard anodize dyed (MIL-A-8625, TY III, CL 2), and non-destructive testing and florescent penetrant inspection (ASTM E1417/E1417M21).

Approvals by Major Aerospace Manufacturers

Aero Plating operates in an 8,500-square-foot facility that is certified to 9001:2015/AS9100D and Nadcap standards for chem-film and passivation applications.Since Aero Plating officially opened its doors in 2023, they have been approved by aerospace manufacturers Eaton Aerospace, Northrop Grumman, Parker Hannifin, Raytheon, and several others.

Aero Plating operates in an 8,500-square-foot facility that is certified to 9001:2015/AS9100D and Nadcap standards for chem-film and passivation applications.Since Aero Plating officially opened its doors in 2023, they have been approved by aerospace manufacturers Eaton Aerospace, Northrop Grumman, Parker Hannifin, Raytheon, and several others.

But for all that the company is accomplishing today, it seemed to Orantes that it might never happen, and his dream of owning a business might remain that: just a dream.

It began in 2017, when Orantes and his wife joined forces with a partner to bring the idea of opening a finishing operation to reality. Orantes had been general manager of a chrome finishing operation for almost two years in 2011 when he left for another industry.

For the past 12 years, Orantes has served as Director of Sales for Aero Bending Company, where he currently works, and hopes to transition full-time to the finishing operation within the next few months. For now, his wife runs the administrative side of the business full-time, and he has hired a production manager to run the operations.

Paperwork and Permits Issues with City Officials

Aero Plating officially opened its doors in 2023, they have been approved by aerospace manufacturers Eaton Aerospace, Northrop Grumman, Parker Hannifin, Raytheon, and several others.In 2017, the Orantes and their partner filed paperwork and permits with Lancaster officials and the South Coast Air Quality Management District to run an electroplating and anodizing operation, but things didn’t go as planned.

Aero Plating officially opened its doors in 2023, they have been approved by aerospace manufacturers Eaton Aerospace, Northrop Grumman, Parker Hannifin, Raytheon, and several others.In 2017, the Orantes and their partner filed paperwork and permits with Lancaster officials and the South Coast Air Quality Management District to run an electroplating and anodizing operation, but things didn’t go as planned.

“We hit some major roadblocks,” Ortantes says. “They started rejecting everything we were sending them. It was very frustrating.”

No matter what Aero Plating was submitting, the city and regulators would say no. It got to the point where Orantes’ partner in the business decided to step aside from the project.

“He said, ‘Doug, we're not getting anywhere,’” Orantes recalls. “I decided to shut down the corporation because we had to keep paying taxes even though we were not operating. In California, they still ding you with taxes, so it's too expensive, and we didn’t have money.”

Although it was a setback, Orantes continued to try with city officials for several years. He remained in contact with them and explored ways to obtain approval for the business and its operations. It wasn’t until 2023 when he talked to a different official in Lancaster who noticed something on Orantes’ applications for Aero Plating.

Finding the Right Person to Say ‘Yes’

“I finally hit the right person who said, ‘Oh, you are in the system as a chemical manufacturer,’” Orantes says. “I explained to them that I was not manufacturing chemicals, but I'm using chemicals within my manufacturing process. And they said, ‘Okay, that changes everything.’”

“I finally hit the right person who said, ‘Oh, you are in the system as a chemical manufacturer,’” Orantes says. “I explained to them that I was not manufacturing chemicals, but I'm using chemicals within my manufacturing process. And they said, ‘Okay, that changes everything.’”

What changed was the way Orantes and his wife, Loida, could get the company up and running; they first needed to find adequate space for their headquarters. He says they looked at “nearly a hundred facilities” before deciding on the one they now call home, and they soon had all the necessary permits from the city.

They met with Ronatec — a Los Angeles-based supplier of chemicals, equipment, and related services to the finishing industry — to help them design and build the system.

“It is much easier to work on everything when you have a blank canvas to do it the right way the first time. We don't have to retrofit where we're band-aiding old equipment and putting in something new, which we do half the time. The building was empty, so the process steps were fairly simple to plan out.”

Orantes says working with owner James Wetherald and his team at Ronatec was very helpful, as their experience working in the industry was apparent in their installations.

”It was great working with Ronatec, and it was a great experience,” Orantes says. “We have little hiccups here and there, but that's normal when you're starting a business.”

Line Installation On Budget but with Great Features

Wetherald says his Ronatec team enjoyed the project, too, as well as working with Orantes.

“He's a great dude, and he wanted it done professionally,” Wetherald says. “He did not hold back on expenditures, but we did it on a budget. His team jumped in and did a lot of the work, which works out well because the way our lines ship, everything's a kit.”

And instead of doing a rebuild or upgrade, Wetherald says the Ronatec team liked working from scratch on designing the system from the ground up.

“The ease of install is amazing, and you're able to install them in hours and not months. A traditional boiler system has black pipes and you're threading it, or you're doing copper, so you're sweating it, or combo the two. If you're working with semiconductors, then you're likely using stainless steel. It's expensive.”

“It is much easier to work on everything when you have a blank canvas to do it the right way the first time,” he says. “We don't have to retrofit where we're band-aiding old equipment and putting in something new, which we do half the time. The building was empty, so the process steps were fairly simple to plan out.”

Orantes says that as they become accustomed to running the lines, they are making minor adjustments and tweaks that come with installing a new system that has never been run before.

“When you are putting a line in from scratch, there are a lot of things that you don't think of when you're installing these things,” he says. “We've been doing modifications to the line as we go. As needed, we call Ronatec, and they come to make modifications and adjust the line to meet our requirements. It's been a great experience with them, and it’s been pretty amazing.”

One of the unique features of the Aero Plating line is the use of a microboiler to heat the lines for processing. Ronatec has been installing them for the last five years, and Wetherald says they have enormous value for shops like Orantes, especially given their location in California.

One of the unique features of the Aero Plating line is the use of a microboiler to heat the lines for processing. Ronatec has been installing them for the last five years, and Wetherald says they have enormous value for shops like Orantes, especially given their location in California.

Using Microboilers to Heat Tanks Has Added Advantages

One of the unique features of the Aero Plating line is the use of a microboiler to heat the lines for processing. Ronatec has been installing them for the last five years, and Wetherald says they have enormous value for shops like Orantes, especially given their location in California.

Wetherald says he was working on a project in France for a German company, and after he shipped the line over, they conducted a live video preview for him, where he first saw the microboilers in action. He was sold on the idea immediately.

Rafael Dominguez“They wanted Schedule 80 CPVC for the plumbing, which he set up in the system, but I thought that was sort of weird,” Wetherald says. “When we were watching the live video, I saw this small white box and asked them what it was, and that is when they showed me it was the boiler. I got off the phone with those guys and I called my wife and said, ‘I'm flying to Paris tonight.’”

Rafael Dominguez“They wanted Schedule 80 CPVC for the plumbing, which he set up in the system, but I thought that was sort of weird,” Wetherald says. “When we were watching the live video, I saw this small white box and asked them what it was, and that is when they showed me it was the boiler. I got off the phone with those guys and I called my wife and said, ‘I'm flying to Paris tonight.’”

Since then, Ronatec has worked to install the microboilers at most of their installations; Wetherald says about 80% of the installations have the systems.

“The ease of install is amazing, and you're able to install them in hours and not months,” he says. “A traditional boiler system has black pipes and you're threading it, or you're doing copper, so you're sweating it, or combo the two. If you're working with semiconductors, then you're likely using stainless steel. It's expensive.”

Wetherald says he can link several of the microboilers together, and each one produces BTUs below the 200,000 mark required for permitting, which can save time and money for the facility as they work with air quality officials.

“ I can link 20 of them together to get just shy of four million BTUs,” he says. “Now I'm bigger than most large boiler systems for our industry, and it’s exhausting with Schedule 40 PVC.”

Cost is About 80% Less Than Normal Boilers

Wetherald says the cost is about 80% less than a normal boiler would cost to purchase and install, and after energy savings are factored in, it could result in a 90% savings. He says Ronatec has installed about 150 of the units, and not one has failed in the field.

Wetherald says the cost is about 80% less than a normal boiler would cost to purchase and install, and after energy savings are factored in, it could result in a 90% savings. He says Ronatec has installed about 150 of the units, and not one has failed in the field.

“But even if they do go out, it takes about 10 minutes to switch out,” he says.

The only negative aspect of the microboilers is that they will only reach a temperature of around 192°F, which Wetherald says means a shop will not be able to get a tank above 172°F. If a tank requires higher heat, he says they will install an electric heater, which Wetherald says is much safer than what they used to be.

Once the system was implemented, Aero Plating required staff to operate it. In February, they hired Rafael Dominguez as the new Production Manager. He joined them from BG Detection, where he served as both Customer Service Manager and Chemical Processing Supervisor. He was responsible for sales, estimating, customer service, preparing production instructions, and ensuring that production plans met customer requirements.

For Orantes, owning a business has been a lifelong dream and one that has become even sweeter thanks to the hurdles he and his wife had to overcome in getting the operation up and running.

Great Opportunity for New Finishing Operation

He says there is an opportunity for a new plating operation in the Southern California area because many are closing down due to being unable to meet state and local environmental regulations.

He says there is an opportunity for a new plating operation in the Southern California area because many are closing down due to being unable to meet state and local environmental regulations.

“There are fewer plating shops in California than there were before,” he says. “There are a lot of machine shops and a lot of competition, but there are not a lot of plating shops, and none up here in the Antelope Valley area. That was what motivated me to open up a plating shop instead of a machine shop.”

His wife was also a driving force in taking this next step, even though both of them are taking huge financial risks. When he became frustrated at the rejections from the city and the long hours it was taking to build the shop — on top of his regular day job — she was always there to support their dream.

Orantes says they cashed in their savings and investments to pay for the new company and its equipment.

“She kept telling me, ‘Doug, it's not going to be forever. We are gonna get through this. Let's get it done,” he says. “There is a moment when your body, your mind, and your heart weaken, and you just want to quit. But when you think about the future — and the benefit your project will bring to the community — that's what makes you continue.”

Finally Able to Run Parts on Finishing Lines

Orantes says it was a big moment when they were finally able to run parts in their finishing lines, and they saw the first parts come off racks. It was a moment to behold for the Orantes and their small team, but it was monumental for all that they had been through.

“When we finished the first job, we praised the Lord because. My wife and I prayed every night to get the opportunity to at least see that we can do it,” he says. “And I think God was very good about that and allowed us to land the first job from Boeing.”

It was only three parts, but that didn’t matter to the Orantes. For them, it was the greatest job they could have taken on. They also got a note from Boeing after they delivered the parts.

“We got a little thank you letter and congratulations, and it said they were happy that we are there to support them,” Orantes says. “ It's exciting now when you think about all the hours you put in, the non-pay, the tiredness, and leaving your kids at home with a nanny because we couldn't be there. Now that we see the company growing slowly but surely, it's like a dream come true. It motivates me to keep working even harder and get to the next stage.”